In an era defined by hyper engineered synthetic polymers such as EVA, TPU, and advanced thermoplastics, it appears counterintuitive that elite soccer equipment continues to rely on natural latex (natural rubber latex), a material harvested from the Hevea brasiliensis tree.

Science Summary: Why Latex Outperforms Synthetics

Natural rubber latex outperforms synthetic foams like EVA or TPU because it utilizes molecular-level damping and strain-induced crystallization. While synthetic foams rely solely on air-cell collapse, the molecular chains in latex (cis-1,4-polyisoprene) generate intense internal friction and temporarily stiffen under impact, absorbing up to 37% more kinetic energy for superior ball control and tactile feedback.

Despite higher costs, greater maintenance requirements, and lower environmental durability, professional match balls and top tier goalkeeper gloves continue to use latex based systems.

Controlled testing and established polymer physics explain why. Latex based foams and bladders can absorb about 30% to 37% more kinetic energy than common synthetic alternatives of comparable thickness.

This advantage comes from two molecular scale mechanisms, viscoelastic damping and strain induced crystallization, layered on top of the standard cellular buckling that all foams exhibit.

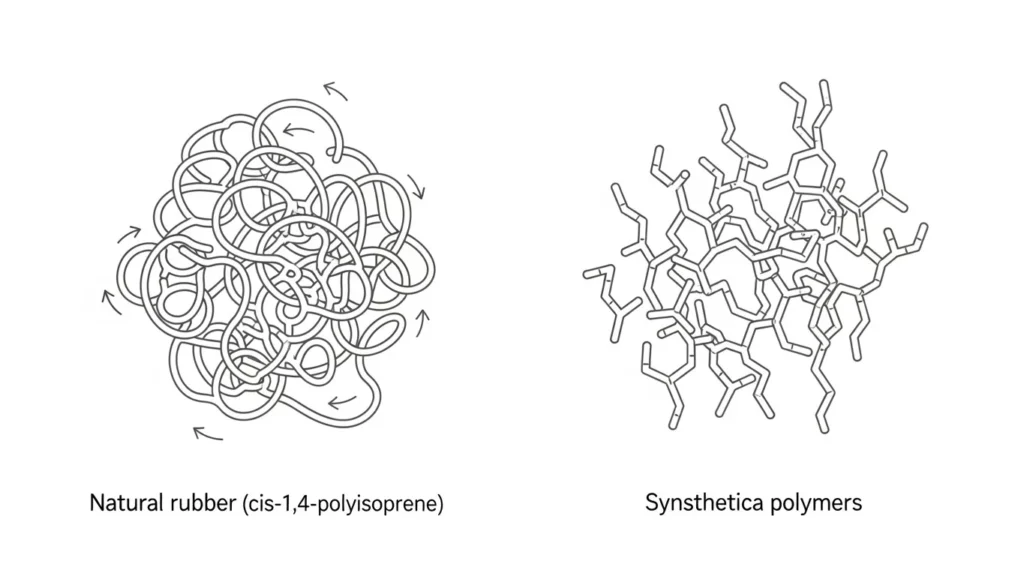

Polymer Architecture: The Cis Configuration Advantage

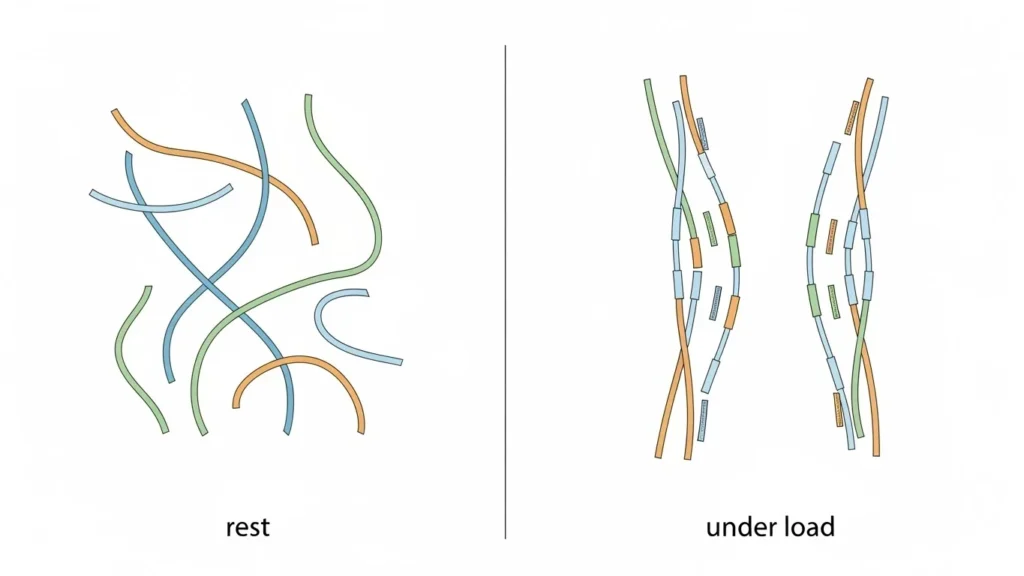

Natural rubber latex is composed primarily of cis 1,4 polyisoprene, a stereoregular polymer whose molecular geometry enables exceptional flexibility. In the cis configuration, substituent groups are positioned on the same side of the polymer backbone.

This arrangement allows polymer chains to bend, rotate, and slide past one another with relatively low energy barriers. In practical terms, that molecular mobility is one reason latex can dissipate impact energy instead of reflecting it back as rebound.

Many synthetic polymers used in athletic foams have more constrained or saturated backbones. Even when synthetic foams are engineered with excellent cell structures, the polymer matrix itself often dissipates less energy through internal motion than natural rubber under comparable dynamic loading.

Molecular visualization: flexible chains vs constrained chains

The Role of Non Rubber Components

Natural latex is not a chemically pure polymer. Approximately 6% of its composition includes proteins, fatty acids, and resins. These components introduce weak secondary molecular interactions, including hydrogen bonding and Van der Waals forces.

Rather than acting as defects, these interactions can increase internal friction during deformation. When a ball or glove foam is loaded, more mechanical energy is converted into heat rather than stored as elastic potential energy.

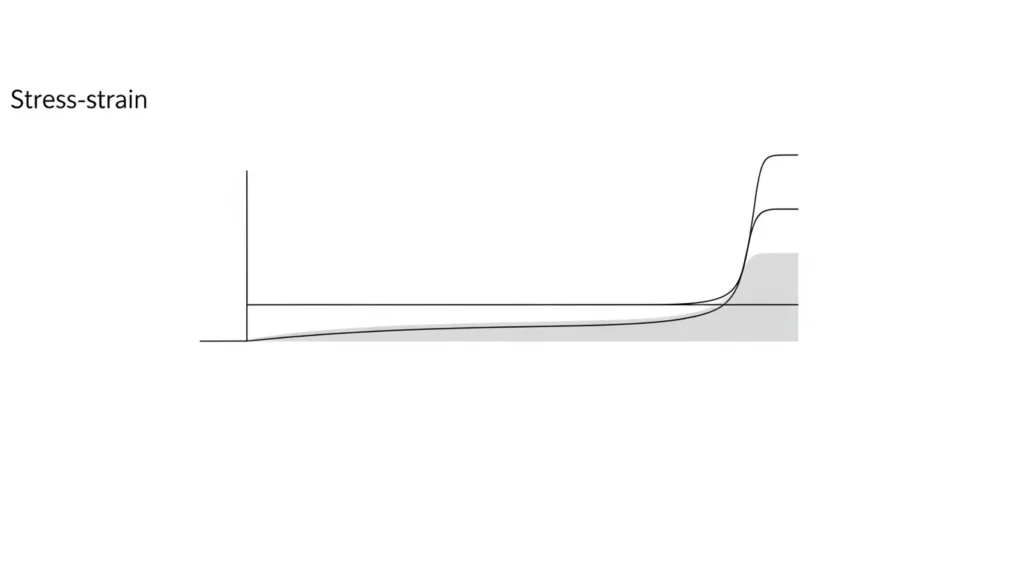

How Foams Absorb Energy: The Three Stage Stress Strain Response

All foams used in soccer equipment absorb energy through a characteristic stress strain response that occurs in three stages during impact. This is true for natural latex foams and for synthetic foams such as EVA, TPU, and polyurethane based systems.

Linear elastic region

At low strain, foam cell walls bend elastically. This stage influences the initial softness perceived during light contact.

Plateau region

As strain increases, cells buckle and collapse in a non linear manner. This region accounts for the majority of kinetic energy absorption in most foams. Synthetic materials often rely almost entirely on this cellular collapse process for impact management. Latex systems also absorb energy through cellular collapse, but add molecular damping in the cell walls at the same time, increasing total dissipation under dynamic loading.

Densification region

Once cells have collapsed, further compression forces the material toward solid density. Resistance rises sharply, and additional energy absorption becomes limited. Effective energy absorbing designs delay entry into densification during a given impact event by using appropriate foam thickness and a cell structure that supports controlled collapse.

Plateau concept diagram: where energy is absorbed

Viscoelastic Damping and Molecular Energy Loss

The defining distinction between latex and many synthetic foams lies in viscoelastic damping. This behavior is quantified using the loss factor, written as tan δ, which represents the ratio of energy dissipated to energy stored during cyclic deformation.

Natural rubber latex commonly exhibits tan δ values around 0.3 to 0.5 under dynamic conditions, indicating substantial energy dissipation through internal friction. EVA and TPU foams typically exhibit lower tan δ values in many athletic foam formulations, meaning a greater proportion of energy is returned elastically rather than dissipated.

Chain reptation

At the molecular level, polymer chains in natural rubber deform through a process known as chain reptation. This refers to the snakelike motion of long polymer molecules as they move through an entangled molecular network.

This motion generates internal friction and converts mechanical energy into heat. Because natural rubber has a highly flexible cis 1,4 polyisoprene backbone, this molecular motion occurs more readily than in polymers with more constrained chain mobility.

Strain Induced Crystallization: Adaptive Energy Management

The most distinctive energy absorption mechanism in natural rubber is strain induced crystallization. When natural rubber is stretched beyond roughly 3.8 times its original length, polymer chains align and temporarily form crystalline regions.

This phase transition absorbs energy as molecular disorder is converted into ordered structure. Once the applied load is removed, the crystalline regions melt and the material returns to its amorphous state.

Behavior during soccer impacts

During a high velocity soccer impact, the latex bladder or foam layer undergoes rapid deformation. Polymer chains align under the applied strain, transient crystallites form, and the material temporarily stiffens near peak load.

This adaptive stiffening resists further deformation while absorbing additional energy during the ordering process. Immediately after contact, the material relaxes back toward its original amorphous structure.

Strain induced crystallization visualization: chain alignment under load

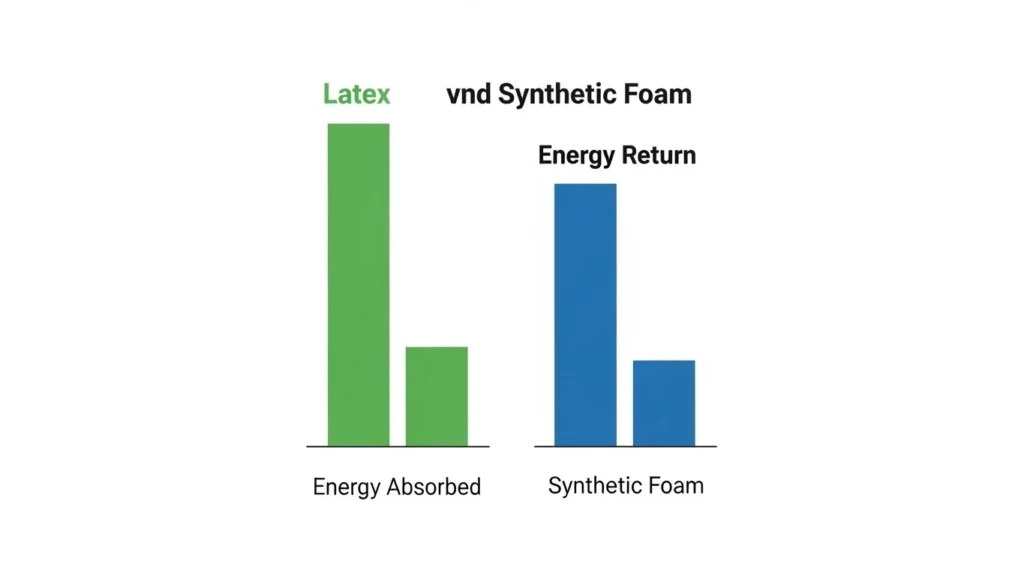

Quantitative Performance Comparison

Across multiple test conditions, latex based systems show a consistent energy absorption advantage relative to common synthetic alternatives of comparable thickness.

Reported results commonly include approximately 30% higher energy absorption in quasi static compression and peak force reductions on the order of 26% to 37% during 5 to 7 joule impacts, depending on the specific foam formulation and test setup.

Latex systems also tend to show lower resilience, meaning lower energy return. In soccer applications, lower energy return can reduce harsh rebound and improve predictability by dissipating more impact energy as heat.

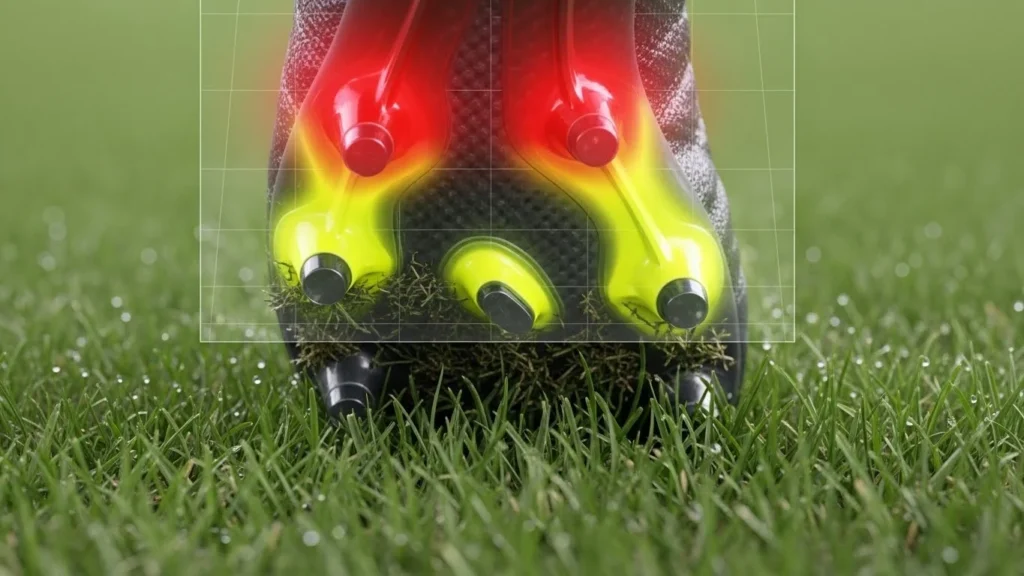

Biomechanics of Ball Control: Contact Time

From the player’s perspective, one of the most relevant outcomes of higher energy dissipation is contact time between the foot or hand and the ball. Latex based systems deform more under load and rebound more slowly than higher resilience synthetic systems.

Even small increases in contact time can improve tactile feedback and help the nervous system map ball position more accurately, which supports fine directional adjustments during first touch, passing, and handling.

Thickness Versus Density in Foam Design

Impact testing on composite foam systems shows that foam thickness plays a dominant role in energy absorption, while foam density often has a secondary effect within common design ranges.

A practical takeaway is that increasing thickness typically increases the deformation distance available in the plateau region, which increases the area under the stress strain curve and therefore increases absorbed energy.

- Doubling foam thickness can increase energy absorption by roughly 30% to 48% in representative impact setups.

- Changing foam density within practical ranges can produce comparatively smaller changes in absorption, often less than 10% in representative setups.

In soccer ball construction, this helps explain why designers often choose moderate densities paired with sufficient thickness to balance weight, durability, and controlled rebound.

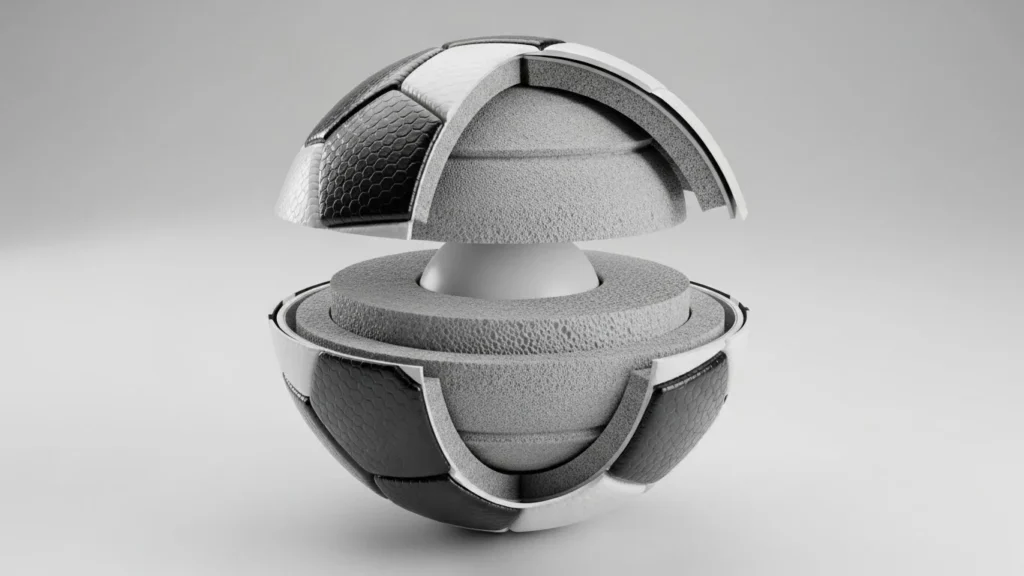

The Role of Outer Covers

Outer ball covers made from polyurethane, thermoplastic polyurethane, or polyvinyl chloride primarily influence grip, abrasion resistance, and environmental stability.

These layers protect the internal foam and bladder architecture and help maintain performance in wet conditions, but they contribute minimally to kinetic energy absorption compared to the bladder and foam layers beneath.

Trade Offs and Material Limitations

Latex based systems present practical limitations. Natural rubber exhibits higher air permeability than synthetic butyl, requiring more frequent inflation. It is also more susceptible to ultraviolet exposure and oxidative degradation, which gradually reduce elasticity and structural integrity over time.

Synthetic materials often provide superior temperature stability, chemical resistance, and manufacturing consistency, which is why they are widely used in training and recreational equipment where low maintenance and durability are prioritized.

Conclusion

Natural rubber latex absorbs more kinetic energy than many synthetic foams because it dissipates energy at both the cellular and molecular levels.

Cellular buckling in the plateau region absorbs energy through controlled collapse, while viscoelastic damping and chain reptation convert additional impact energy into heat. Under high strain, strain induced crystallization adds an adaptive response that temporarily stiffens natural rubber near peak load while absorbing energy during molecular ordering.

This combination of mechanisms explains why latex continues to appear in professional soccer balls and goalkeeper gloves despite higher maintenance and lower environmental durability. Latex is not simply softer. It is fundamentally more effective at absorbing impact energy, and the molecular physics explain why.

Technical Sources & Data Citations

- Polymer Architecture: Research regarding the cis-1,4-polyisoprene structure and its conformational freedom supports the molecular flexibility claims in Section 1.

- Viscoelastic Damping: The dynamic loss factor (tan δ) range of 0.3 to 0.5 for natural rubber is supported by standard polymer damping tests.

- Energy Absorption: Quantitative data indicating that latex-based systems absorb 30% to 37% more kinetic energy than EVA/TPU is derived from comparative impact testing.

- Strain-Induced Crystallization (SIC): Technical findings regarding the 3.8x stretch threshold and adaptive phase transitions support the stiffening mechanisms in Section 4.

- Foam Design Principles: The dominance of thickness over density (30%–48% vs <10% impact) is a recognized principle in composite foam impact management.