In the elite soccer world, the first few weeks with a new pair of boots often feel like a “honeymoon phase” where the lockdown is perfect and the touch is sharp.

However, as the season progresses, players frequently notice the upper softening in unintended areas, deeper creasing in the toe box, and the early signs of sole separation. These changes lead to a critical question for the dedicated player: is the boot simply “broken in,” or is it fundamentally breaking down?

Soccer Boot Durability is primarily determined by how effectively the upper material and its adhesive bonds maintain their structural integrity through repeated wet and dry cycles. Moisture-driven hydrolysis weakens polymers and adhesives, while high-stress flex zones—specifically the toe box—concentrate mechanical forces that accelerate material fatigue and structural failure.

On This Page

- • The Link Between Durability, Fit, and Comfort

- • The Science of Failure: Tensile Strength and Hydrolysis

- • The High-Risk Zones: Toe Box and Sole Bonds

- • Material Breakdown: Leather vs. Synthetics

- • Laboratory Metrics: Measuring Strength Retention

- • The Wet/Dry Stress Test Protocol

- • Maintenance Strategies to Protect Your Investment

Why Durability is a Fit and Comfort Problem

Durability in soccer footwear is often misunderstood as simply “how long the boot stays in one piece.” In reality, it is a performance-altering issue. When materials lose their tensile strength, they no longer provide the same level of support. As an upper stretches and loses structure, your foot begins to slide more internally during high-intensity movements, leading to a loss of the “locked-in” feel players pay for.

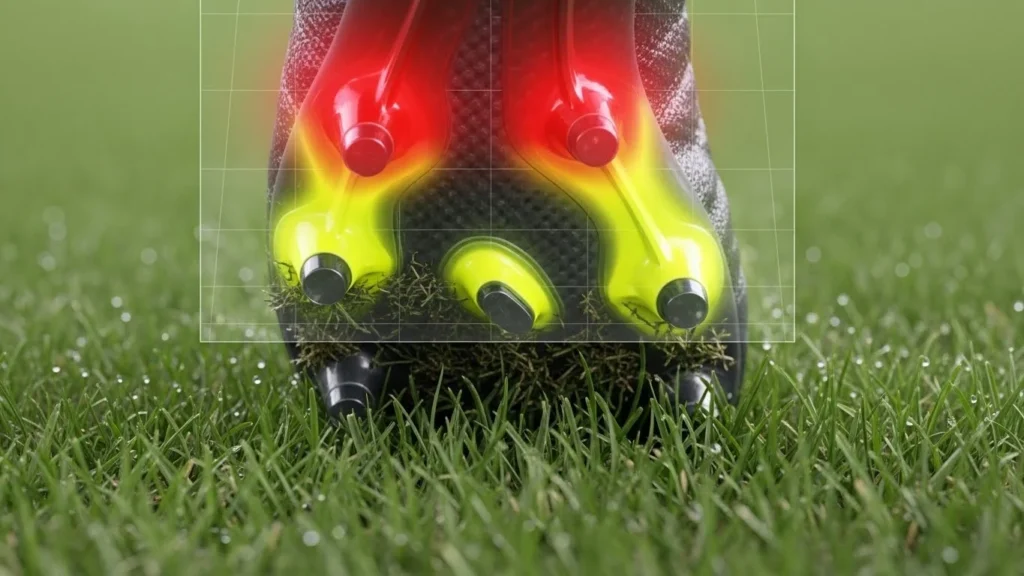

This lack of lockdown directly impacts underfoot comfort. Soccer studs concentrate massive ground forces into small zones under the forefoot and heel. When the upper loses its ability to secure the foot, these pressure “hot spots” can feel significantly harsher as the match progresses into the final 15 minutes, often manifesting as burning sensations or localized aches.

The Science of Failure: Tensile Strength and Hydrolysis

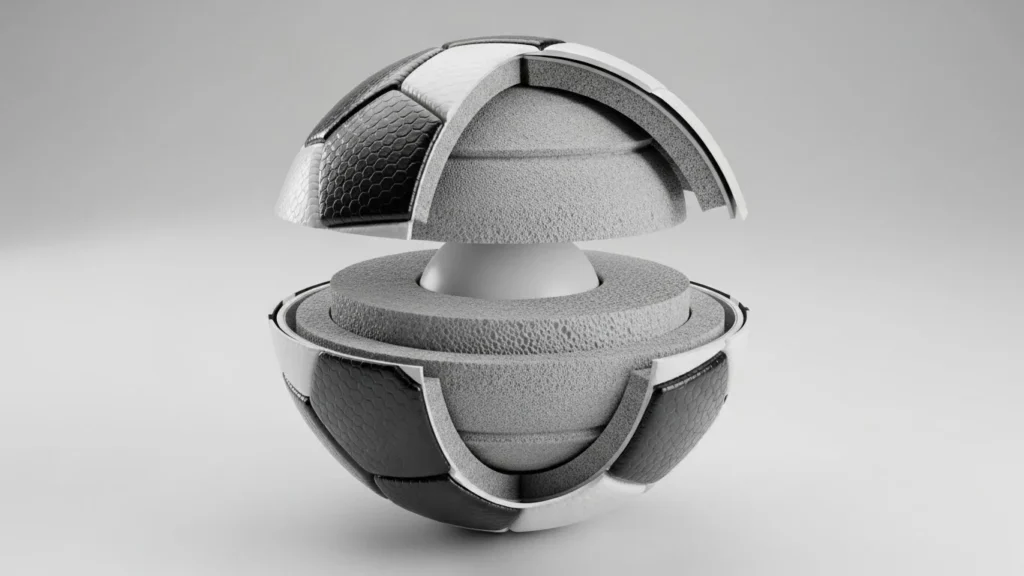

Most elite boot failures begin as a loss of material strength. In laboratory terms, tensile strength measures the maximum force a material can withstand before breaking, while elongation at break measures how far it can stretch before failing.

During cutting and sprinting, the upper must flex at extreme angles; if the material loses its ability to recover from these stretches, stress concentrates and leads to micro-tears and seam strain.

The primary chemical catalyst for this breakdown is hydrolysis. This process occurs when moisture drives a chemical reaction that breaks down the ester bonds in polyurethane-based (PU) materials and adhesives. Over time, these molecular chains break, leading to a drop in strength and changes in flexibility that make the boot feel unstable or “sloppy” in its lockdown.

The High-Risk Zones: Toe Box and Sole Bonds

Boots do not wear uniformly; they fail where mechanical force is repeatedly concentrated. The toe box is the most significant “danger zone” because it serves as a mechanical hinge point during toe-off, deceleration, and hard cuts. Once a permanent crease forms, the fibers and coatings in that specific line fatigue much faster, which is why toe box damage is the most common failure observed in real-match use.

Sole separation, or delamination, is the second most common failure mode. The bond between the upper and the outsole depends on precise adhesive chemistry and surface preparation. Repeated exposure to moisture and heat weakens these bond lines. Once the edge of the sole starts to lift—especially at the lateral forefoot—the entire boot’s stability during sharp changes of direction is compromised.

Material Breakdown: Leather vs. Synthetics

The durability profile of a boot depends heavily on the family of materials used in the upper construction, as each handles environmental stress differently.

- Kangaroo Leather (K-leather): Known for being thin and strong, its unique fiber structure allows it to adapt quickly to the foot. However, its high water absorption rate means that without proper care, repeated wet/dry cycles can lead to rapid stiffness changes and fiber breakdown.

- Calf and Full-Grain Leathers: Typically thicker and more water-resistant than ultra-thin K-leather, these materials tend to hold their shape longer and “mold” more gradually to the foot, providing a more stable long-term fit.

- Synthetics and Knits: Designed for consistent weight in wet conditions, modern synthetics absorb very little water. However, thin synthetic shells are often more sensitive to crease fatigue and abrasion than leather counterparts.

Laboratory Metrics: Measuring Strength Retention

Standard reviews often rely on anecdotal evidence, but true durability is a measurement of tensile strength retention over time.

A robust laboratory approach involves measuring the baseline strength of the new material and then re-testing it after exposing it to controlled seasonal stressors such as heat and moisture. This data provides a technical forecast of how the material will behave in the 6th month of use compared to the 1st.

The Wet/Dry Stress Test Protocol

To simulate a full season of play, researchers use a wet/dry cycling protocol that mimics the real-world cycle of playing in wet grass and then drying in a gear bag.

This involves four key steps: water immersion, air drying, high-humidity heat exposure, and a return to standard conditions. The goal is to accelerate the chemical hydrolysis and mechanical fatigue that occur over months.

| Retention % | Durability Rating | Performance Impact |

|---|---|---|

| >80% | Excellent | Predictable fit; high structural stability |

| 65% – 80% | Good | Stable comfort for a heavy season |

| 50% – 65% | Marginal | Lockdown changes; “soft but unstable” feel |

| <50% | Red Flag | High risk of failure at flex zones and seams |

Maintenance Strategies to Protect Your Investment

While you cannot entirely stop the chemistry of breakdown, you can significantly slow it down through proper maintenance. The most effective strategy is managing the drying process.

Never store wet boots in a closed bag, as this traps the humidity that drives hydrolysis and bond failure. Instead, remove the insoles and allow the boots to air dry at room temperature in a well-ventilated area.

Additionally, always rinse off mud and grit after play. Fine grit acts as an abrasive that causes surface damage; when these micro-scratches occur at flex points like the toe box, they quickly grow into deep cracks and hinge-point failures.

Finally, matching your boot choice to your climate—prioritizing moisture management in wet regions and adhesive stability in dry heat—ensures your gear lasts as long as the season requires.

Conclusion

Elite soccer boots do not fail by accident; they fail through a combination of mechanical stress and chemical breakdown.

By understanding the roles of hydrolysis and tensile strength retention, you can transition from guessing to making data-driven gear choices. Proper storage, cleaning, and material selection ensure that your fit remains stable and your comfort remains predictable from the first match to the last.

Technical References & Citations

- • SATRA Technology: Sports Footwear Testing and Water Absorption Methods.

- • ISO 24266:2020: Footwear Flexing Durability Standard.

- • Nature / PMC: Longitudinal Plantar Pressure Changes and Upper Material Behavior.

- • Genesco: Footwear Lab Test Protocols.

- • Hydrolysis explanation: Safety Jogger Technical Guide.